Labels for Test Tubes

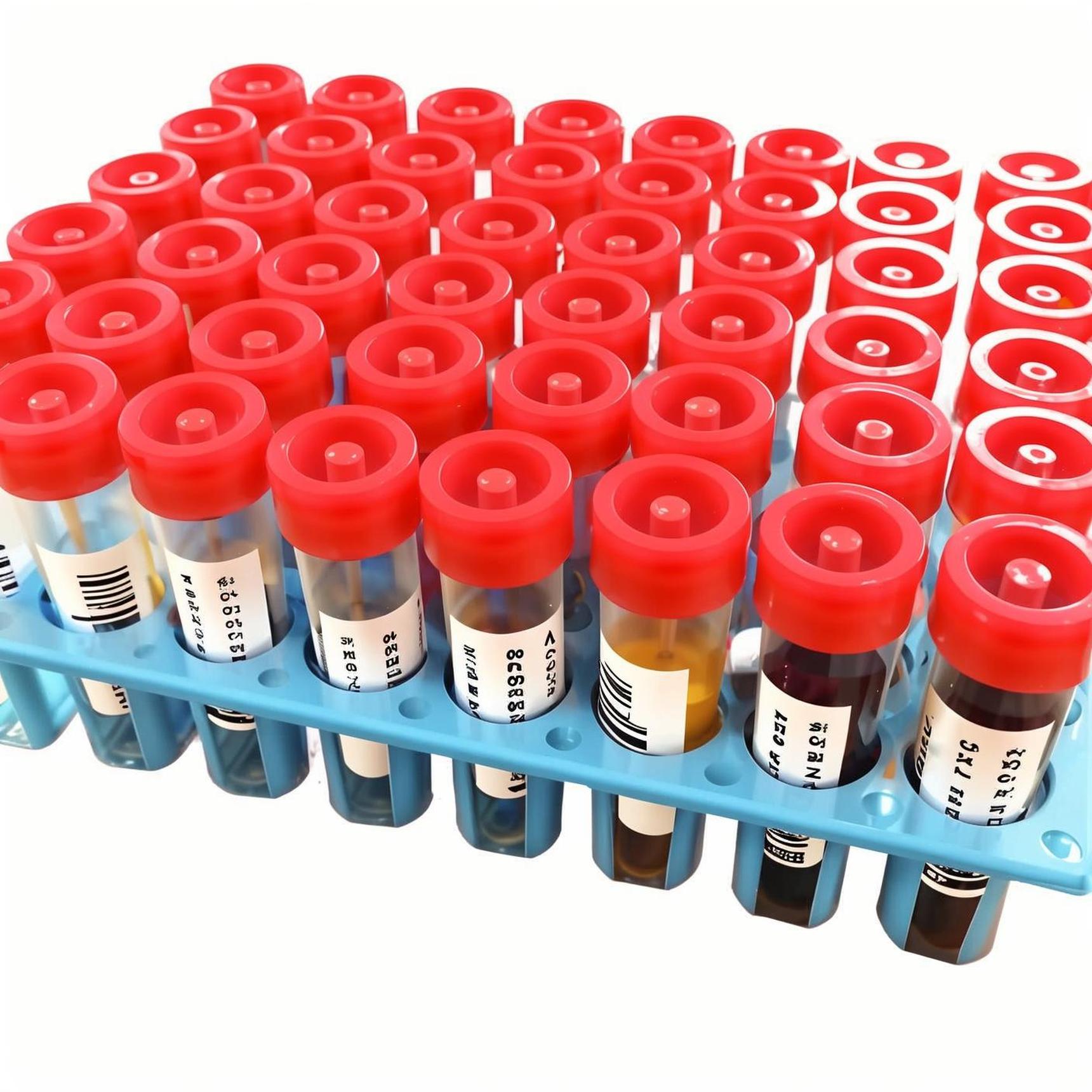

A medical adhesive label for test tubes is a highly specialized label used in healthcare, laboratory, and diagnostic environments. These labels are designed to ensure precise identification of samples under various challenging conditions, providing critical information such as patient details, test types, and tracking codes. Given the unique demands of the medical and lab sectors, test tube labels must meet stringent functional requirements.

Key Features:

1. Strong Adhesive for Small Diameter:

One of the critical requirements for test tube labels is the ability to adhere securely to surfaces with a small diameter, such as test tubes. The adhesive must be strong enough to prevent the label from peeling or curling at the edges (also known as "flagging"). This is particularly important because test tubes have a curved and narrow surface, and the label must wrap around tightly while maintaining its integrity.

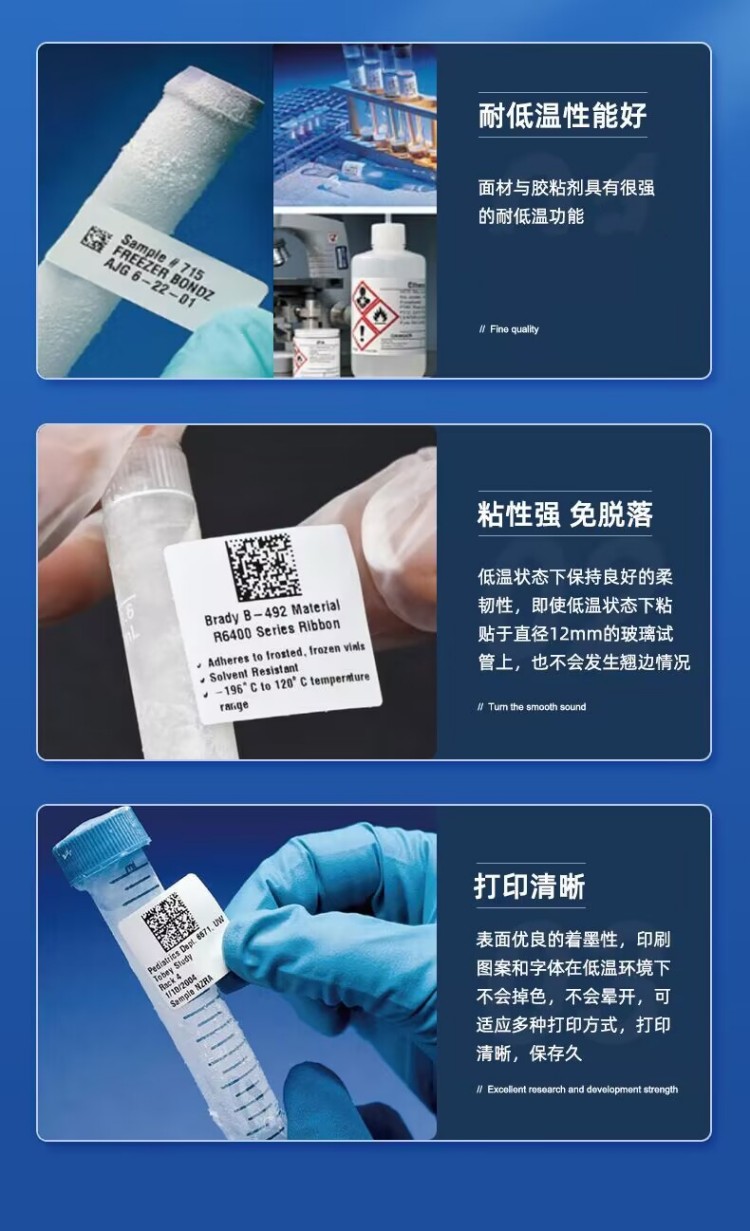

2. Low-Temperature Resistance:

Many medical and laboratory environments require the storage of samples at extremely low temperatures, such as in cryogenic freezers. The labels must be engineered to remain adhesive and legible even when exposed to temperatures as low as -80°C or lower. Whether the sample undergoes freezing, thawing, or repeated temperature changes, the label must stay firmly in place without degradation.

3. Durability Against Chemicals and Moisture:

Test tube labels often encounter chemicals, solvents, and moisture, especially during processes like centrifugation, cleaning, or storage. The materials used for these labels are resistant to various substances, including water, alcohol, and chemical reagents, ensuring that the printed information remains intact and the label does not disintegrate or smear.

4. Write-on Surface:

In some medical applications, it's essential for staff to handwrite additional information directly onto the label surface, such as notes or specific instructions. These labels are designed with a writable surface that allows for manual notation using pens or markers. This write-on capability ensures flexibility in labeling, especially in situations where printing is not feasible, or additional on-the-spot information needs to be added.

5. Clear and High-Resolution Printing:

The labels are compatible with a variety of printing methods, including thermal transfer, direct thermal, laser, or inkjet. These printing methods allow for high-resolution barcodes, QR codes, patient IDs, and other critical information. The print must be smudge-proof, resistant to fading, and maintain legibility over time, regardless of exposure to extreme conditions.

6. Non-Toxic and Medical Grade:

These labels are manufactured from non-toxic, hypoallergenic materials that comply with medical and healthcare standards (such as ISO 10993 and FDA regulations). This ensures that the labels do not introduce contamination to the samples or react with the materials inside the test tubes.

7. Custom Shapes and Sizes:

Test tube labels can be customized in terms of size and shape to match different tube diameters and surface areas. This flexibility ensures that the label fits perfectly around the tube, avoiding issues like folding or misalignment that could obstruct critical data.

8. **Tamper-Evident Options**:

To ensure sample security, some labels are designed to be tamper-evident. If the label is removed or altered, it will leave visible signs of tampering, such as a "void" mark or a broken pattern, which signals unauthorized access.

9. Label Flexibility and Conformability:

The label material is engineered to be flexible, allowing it to wrap smoothly around small-diameter tubes without causing wrinkles or air bubbles. The ability to conform to curved surfaces is essential in ensuring the entire label stays adhered to the tube for the duration of its use.

Applications:

- Sample Identification: For marking blood, tissue, or other biological samples with essential information such as patient ID, sample type, and test date.

- Barcode Tracking: High-resolution barcodes or QR codes enable automated tracking of samples through various stages of testing, handling, and storage.

- Handwritten Notes: When necessary, medical staff can manually write additional information onto the label surface without compromising readability or adhesion.

- Low-Temperature Storage: Labels used for samples stored in cryogenic freezers or under other extreme conditions require reliable adhesion and legibility, even in environments below freezing temperatures.

Summary:

Medical adhesive labels for test tubes are an indispensable part of modern healthcare and laboratory processes. With features such as small diameter adhesion, low-temperature resistance, chemical durability, and the ability to handwrite on the surface, these labels offer a reliable solution for precise and durable identification of critical medical samples. They are designed to perform under extreme conditions, ensuring that both the label and the data it holds remain intact and legible throughout the sample’s journey.